Heating method of the hard wadding oven is by burners or electrical heating. The circulating fan will penetrate and convent the hot air through the air duct and blow it in the opposite direction to achieve the maximize energy saving.

This oven can be used to produce hard wadding product, like glue-free product, silk-like product, wool insulation, wool quilts, etc., which is widely used in clothing, embroidery, bedding, furniture, travel products, etc. The oven can be heated by three burners, and three circulating fans will penetrate the hot air through the air duct and blow it against each other to achieve the maximum hot air. The two-layer mesh belt is driven in an integrated manner and adopts frequency conversion control. (Can be customized)

Working Width:2500mm-3000mm

Weight: About 16000-20000KG

Working Speed:3-20m/min

Conveyor belt (customized): Double Layers Teflon mesh belt

Temperature control range in the oven box:≤200℃

Heating Mode: Natural Gas

Total Power: About 106-110 KW

Main Features:

(1)Heating method: one burners are used for heating or electrical heating. The circulating fan will penetrate and convent the hot air through the air duct and blow it in the opposite direction to achieve the maximize energy saving.

(2) The main machine frame is welded with 120mm square tube and connected with 120mm square tube; Stable structure.

(3)The transmission mesh roller is chrome plated after fine grinding of seamless steel pipe.

(4)The front and rear curtains frame are 1.5m long, effectively ensuring deviation correction and stable operation of the motor.

(5)The three-layer mesh belt drives integrally and adopts frequency conversion control;

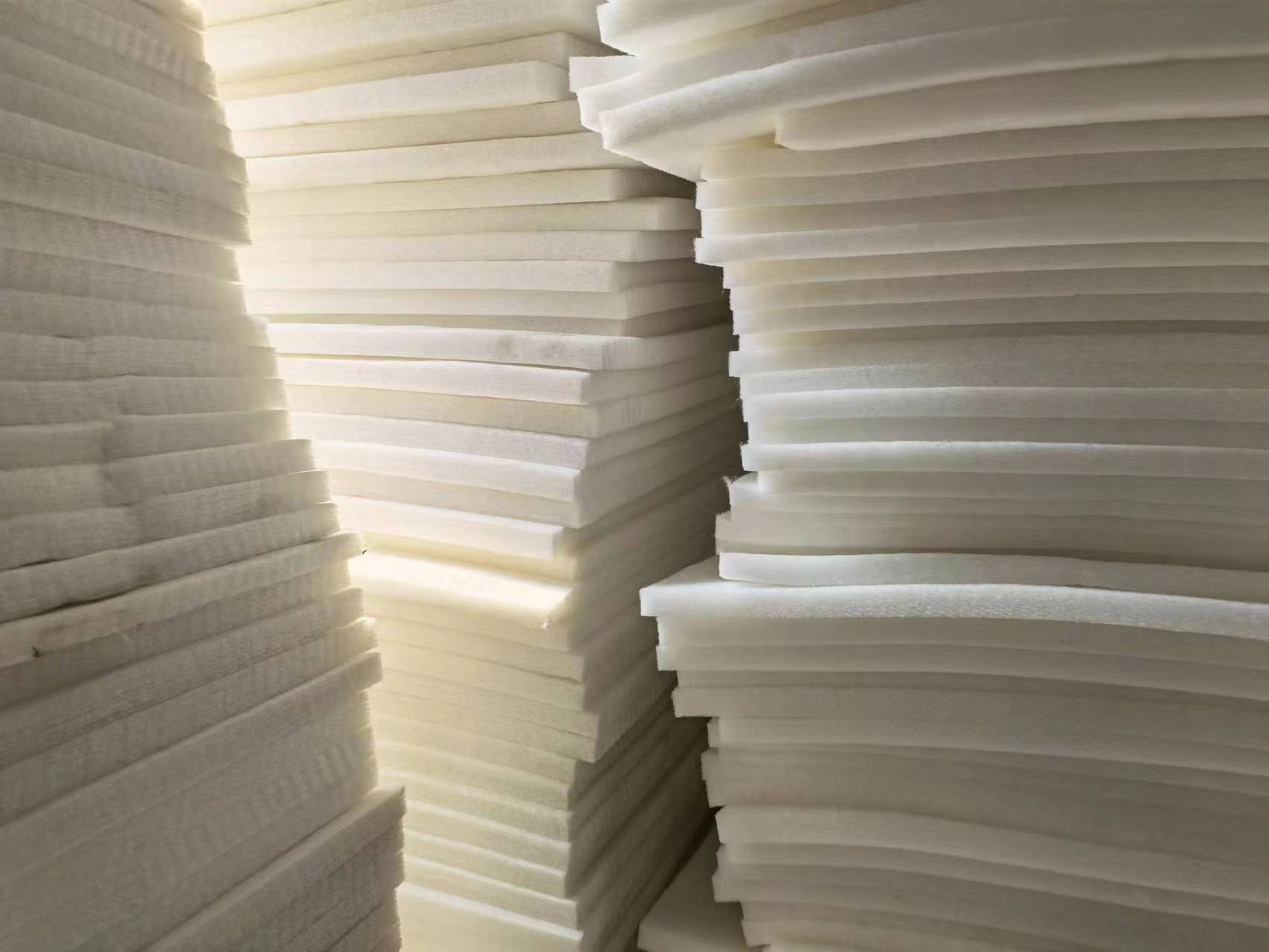

Final Product:

Hard Wadding For Mattress Polyester Fiber For Quilts Glue-free Product