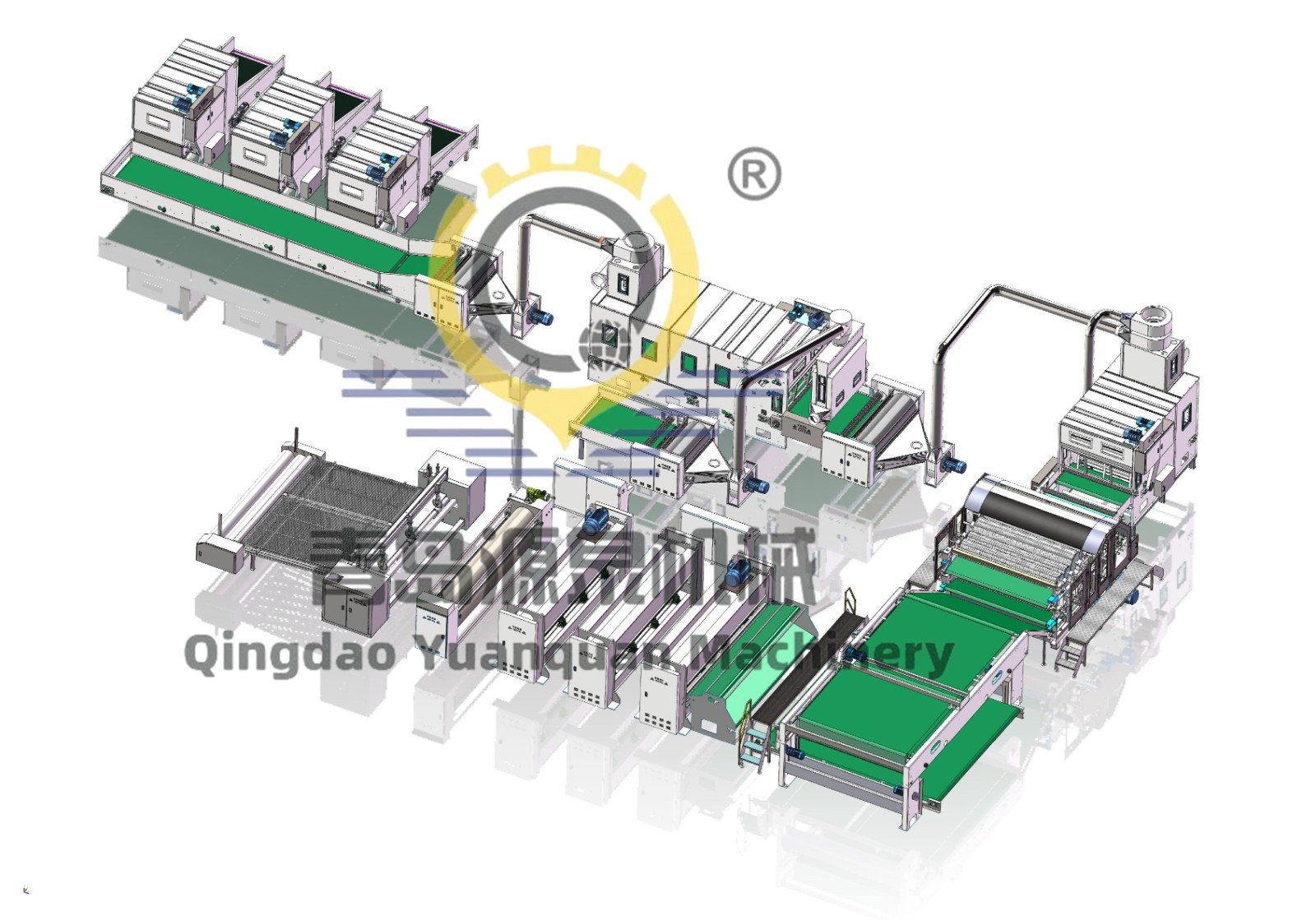

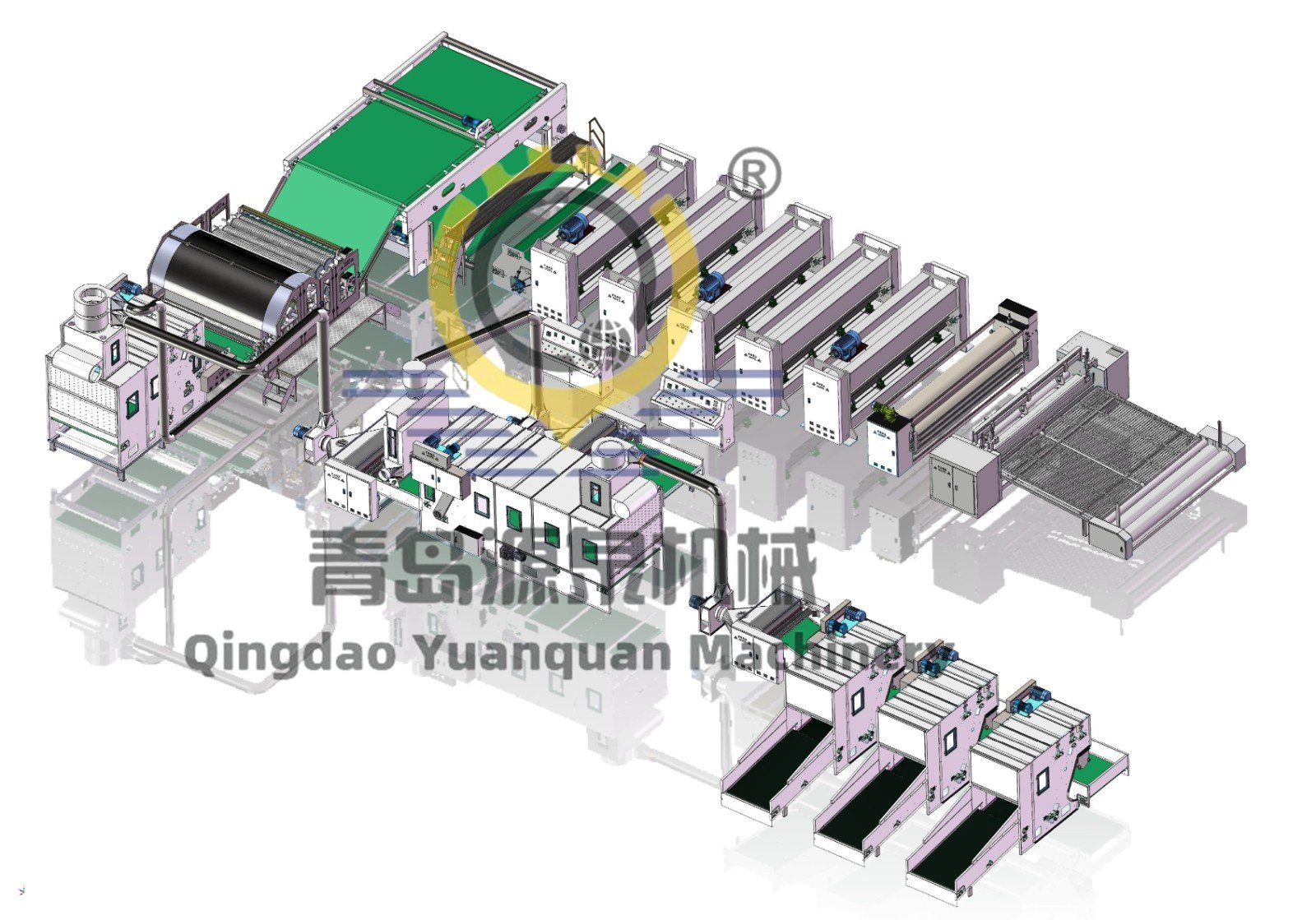

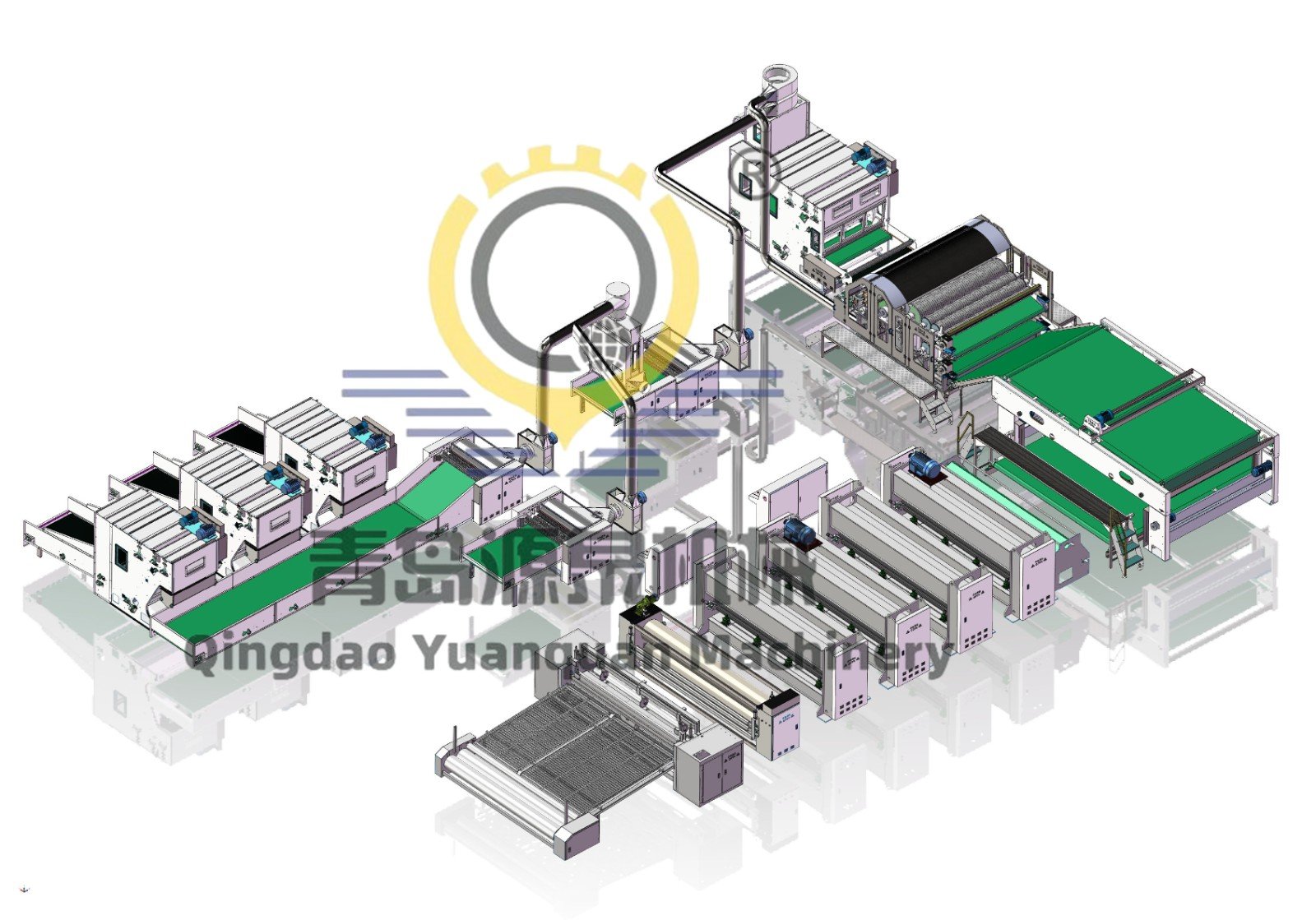

Application: Suitable for general non-woven fabrics, such as needle-punching production line, linoleum base fabric production line, geotextile production line, carpet production line, quilt production line, automotive interior non-woven fabric production line, synthetic leather base fabric production line,scouring pad production line, etc. Can be customized according to customers'needs.

Product Summary: Needle Loom Production Line

Input Material:Sheep Wool, Polyester fiber or other chemical fiber

Processing:

Line Speed: 1--8m/min

Weight: 80g--600gsm

Thickness of the finished product: 5--80mm

Max Working Width:2500mm or customized

Max width of finished product after cutting: 2600mm

Voltage:380 V(3-phases) 50 HZ

Capacity: About 100-600 kg/h (for sheep wool

For Quilts For Felt For Blanket